Tarsus Footplates

Footplates for Secure PCMS Deployment

Cleated and rubber Tarsus Footplates help keep portable changeable message signs in place on soil, gravel, asphalt, concrete, and sloped surfaces, supporting precise Spyder Platform deployment.

Product Overview

Grip. Traction. Placement.

Tarsus footplates integrate with the Spyder Platform to provide a compact, low-profile support system, with cleated and rubber designs that help keep PCMS setups positioned as planned during changing jobsite conditions.

The footplate swivels to allow flexible placement and improve contact with the surface.

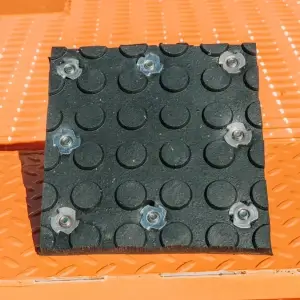

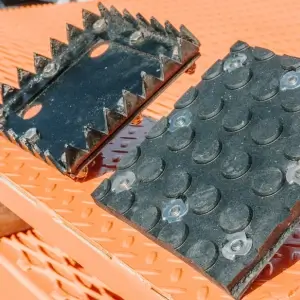

Cleated metal footplate grips the surface to prevent sliding and maintain placement.

System Architecture

Cleated and rubber footplate design, swivel behavior, and mounting details that support secure placement and long-term value.

Tarsus Footplates pair with Spyder Legs to increase platform stability on paved, gravel, and mixed jobsite surfaces, providing a more secure footing for portable changeable message boards across multiple applications.

Metal cleated or rubber Tarsus Footplates use a swivel-mounted design to maintain maximum ground contact on uneven or sloped terrain, using iron sawtooth engagement in soil or a rubber contact surface on asphalt and concrete to create high-friction, purpose-built ground contact for Spyder Legs.

Tarsus Footplates convert sawtooth cleats in soil and rubber ground contact on hard surfaces into holding power, keeping Spyder Legs planted under wind load and on mixed or sloped terrain so the platform stays stable without sandbags or unplanned repositioning.

High-friction Tarsus Cleated Footplates let crews deploy Spyder Platforms farther from the travel lane on sloped or soft ground, reducing collision exposure while skipping sandbags and safeguarding the PCMS.

Applications

Field Deployment Use Cases

Spyder Legs support leveled deployments on graded shoulders, gravel, compacted soil, and other suitable set‑back sites.

Graded Shoulders

Maintains a level Spyder deployment on compacted, graded shoulders where the surface slopes away from the roadway. The portable changeable message sign remains level and secure for set‑back deployments clear of traffic.

Unpaved Medians

Provides 29″ of vertical adjustment on unpaved medians so the Spyder Platform/Base can sit level on contoured or sloped ground, bridging minor grade changes and distributing platform load into stable ground contact locations.

Access Points

29″ swing‑out jack stands accommodate elevation changes at access points where pavement transitions to soil or grass, keeping the Spyder Platform/Base level while transferring load into defined support points beyond the lane edge.

Technical Overview

Specifications & Details

Metal cleated and rubber Tarsus Footplates use swivel-mounted designs and surface-specific friction to stabilize Spyder Legs on soil, gravel, asphalt, and concrete.

Model 100700

Terrain & Slope

-

Swivel-mounted ground contact

-

Recommended slope up to 22 degrees

Hard-surface Deployments

-

Rubber contact surface

-

Max friction on asphalt and concrete

Soil Deployments

-

Metal sawtooth cleats

-

Max friction in earth and gravel

Use Constraints

-

Cleats: soil only

-

Rubber: asphalt/concrete

Included Components

- Standard on Spyder systems: Each Spyder Platform and Spyder Base includes four Tarsus cleated footplates.

- Orderable cleated sets: Additional Tarsus cleated footplates available as single units or sets of four.

- Orderable rubber sets: Tarsus rubber footplates available as single units or sets of four for hard-surface deployments.

Related Products

Spyder Platform

Full-Size Full-Matrix Portable Changeable Message Sign

Spyder Base

Retrofit solution for damaged trailers.

The Jeep

Dedicated transport trailer for Spyder Platforms.

Spyder Legs

29″ adjustable 5000 lb swing-out jack stands.

General Information

Frequently asked questions

Can the Tarsus Cleated Footplates help reduce collisions?

Yes. Spyder Legs and Tarsus Cleated Footplates work together to support the Spyder Platform and Spyder Base on soil, gravel, and sloped surfaces up to a 33% grade.

The extended placement capabilities allow crews to position message boards farther from active travel lanes to reduce collision risk while maintaining required visibility and siting constraints.

How are Tarsus footplates used in a standard deployment?

Each Spyder Platform and Spyder Base is supported on four Spyder Legs, with a Tarsus footplate attached at the bottom of each leg, and cleated or rubber variants selected to match the approved soil or hard-surface conditions at the site.

How many Tarsus cleated footplates are included with a Spyder Platform or Spyder Base?

Each Spyder Platform and Spyder Base includes four Tarsus cleated footplates.

Are Tarsus footplates removable in the field?

Tarsus footplates are designed to be easily removable so crews can swap between cleated and rubber footplates in a few minutes when deployment placements change, such as moving from soil or aggregate areas to finished asphalt or concrete surfaces that need protection.

Can additional Tarsus footplates be ordered?

Yes. Both Tarsus cleated and Tarsus rubber footplates are available as add-ons, and can be ordered as single footplates or in sets of four. Contact INEX to order.

What are the intended applications for cleated vs. rubber Tarsus footplates?

Cleated Tarsus footplates are intended for soil and other unimproved ground where the cleats engage for additional stability, while rubber Tarsus footplates are intended for hard surfaces such as asphalt or concrete in off-roadway locations where surface protection is required.

Have Questions?

Talk With Our Team

Contact